|

|

Rothenberger ROWELD Band Saw Machines BS 450. BS 630M, BS 630 Plus, BS 800 Plus, BS 1200 Plus, BS 1600 Plus

|

|

|

RIEXINGER BSM-450 BAND SAW MACHINE

Ø 50mm - 450mm |

|

|

|

|

Riexinger BSM 450 Plastic pipe band saw Ø 50 - 450 mm The BSM 450 electric band saw is specially designed for the precise cutting of plastic pipes in the diameter range from 50 mm to 450 mm. The machine impresses with its robust and torsion-resistant steel construction, which is used for both the machine stand and the saw frame. With a well-thought-out saw blade deflection that runs on ball bearings and a spring-supported blade tensioning device, the BSM 450 ensures maximum cutting precision and durability. All advantages at a glance Robust construction: machine stand and saw frame made of torsion-resistant steel. Precise deflection: saw blade deflection with ball bearings for smooth operation. Angle cuts: Pivoting saw bow for angle cuts from 0° to 45° (infinitely adjustable). Safety: ON-OFF switch with motor protection and brake electronics for safe working. |

|

|

|

|

|

|

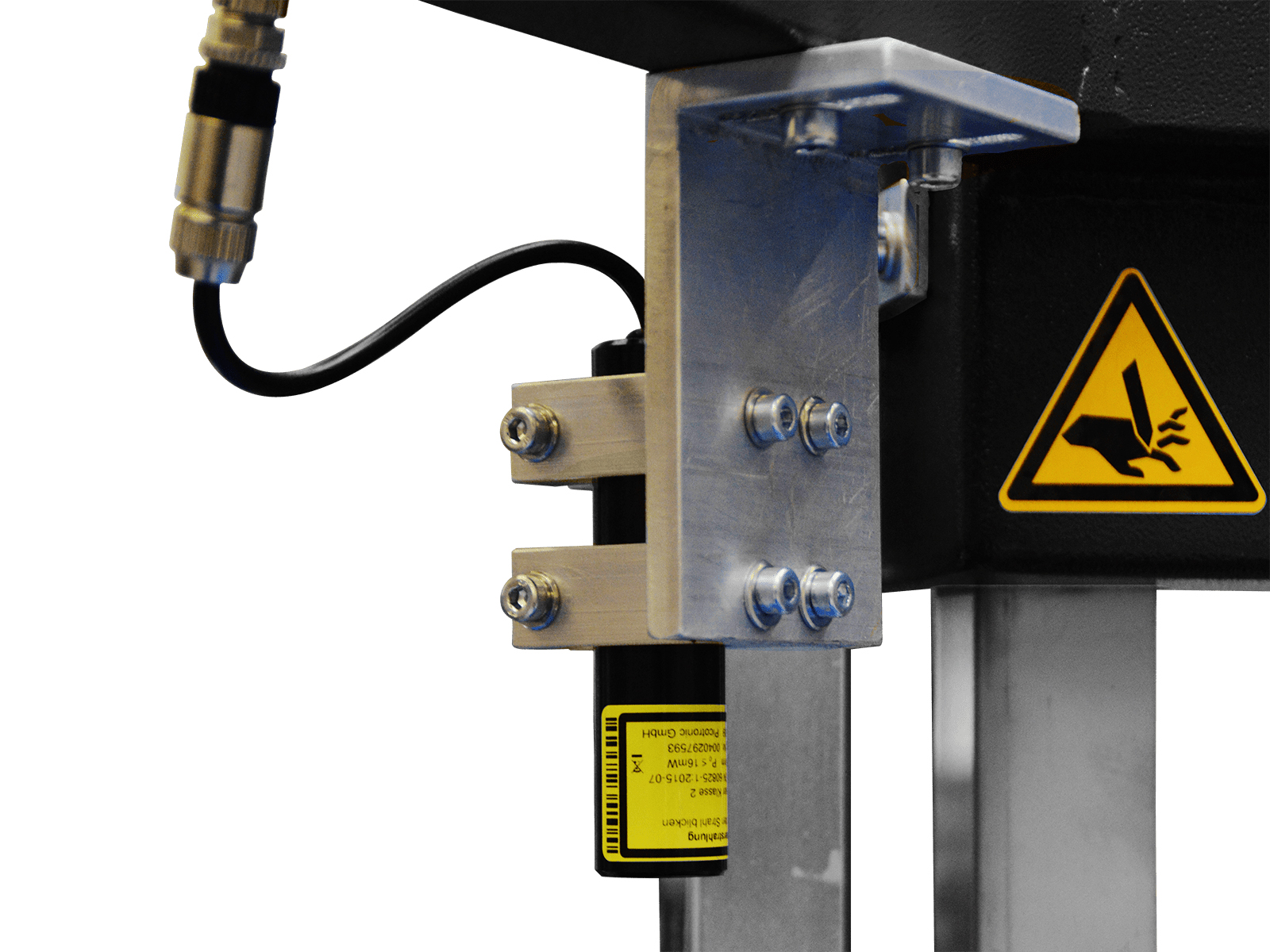

Laser device for cut detectionThe laser device for cutting detection for the BSM 450 enables precise and automated detection of the cutting lines. This significantly improves accuracy and efficiency when sawing pipes.

|

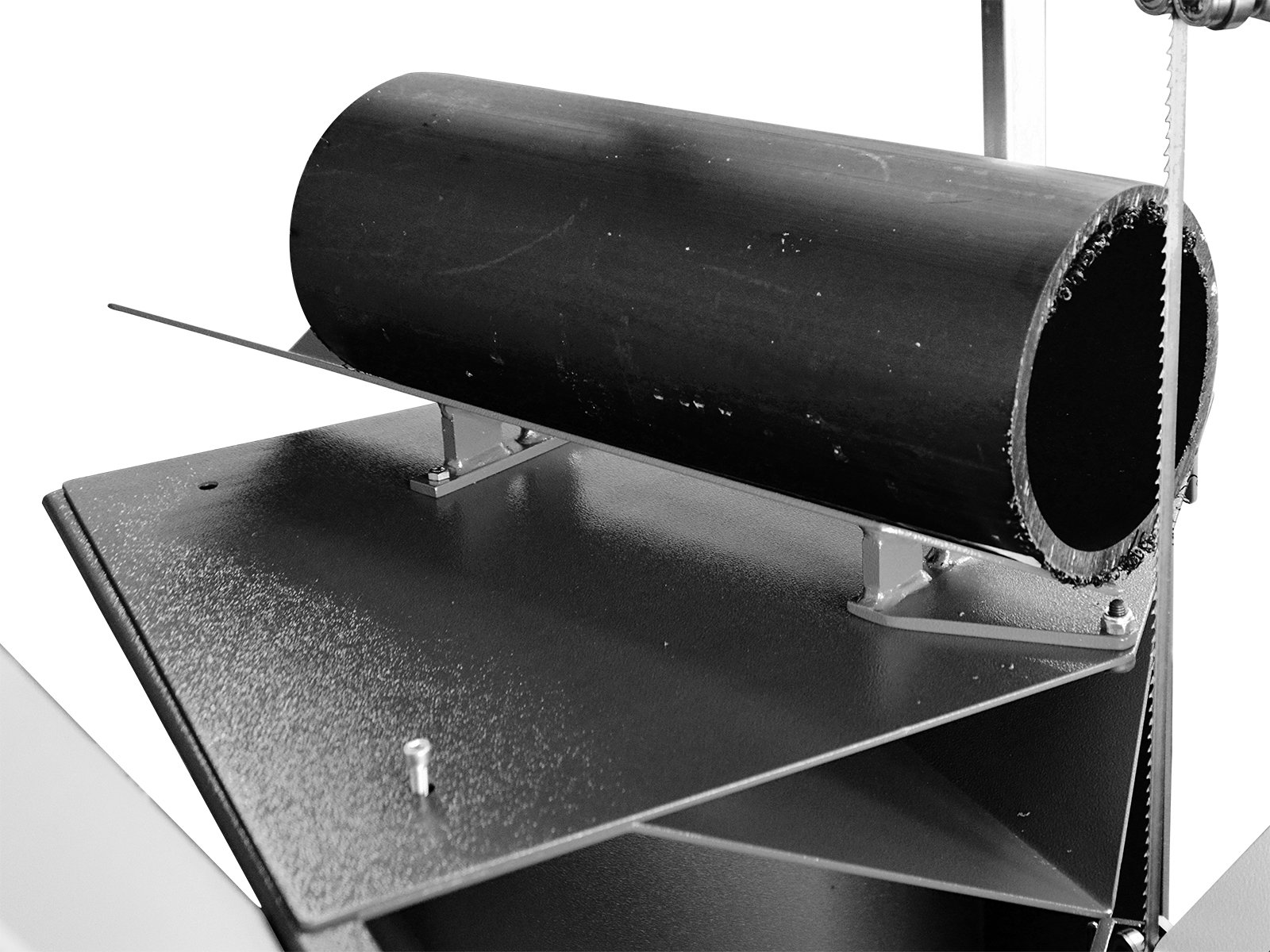

Auxiliary device for radial cutsThe BSM 450 radius device is designed for precise face sawing of radii for saddle welding. It can process pipes with a maximum diameter of 270 mm. The sawing radius can be adjusted from 63 mm to 330 mm and the sawing angle can be varied between 0° and 45°.

|

Attachment table for angle cuts 67.5°The attachment table for 67.5° angle cuts enables precise and stable cuts at a fixed angle of 67.5°. Ideal for special applications that require precise angle cuts.

|

|

|

|

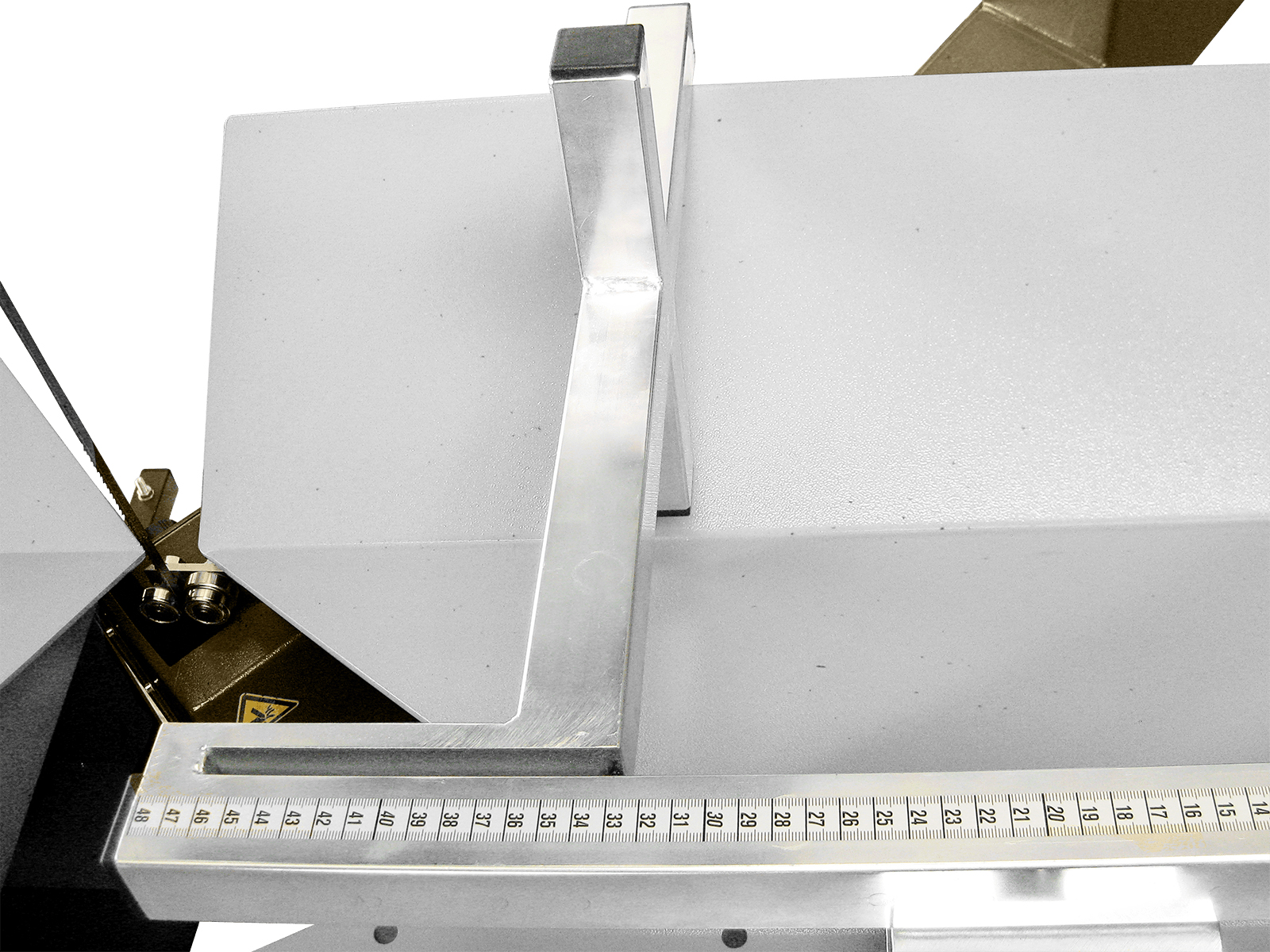

Length stopThe BSM 450 cross-cut fence enables precise settings in the length range from 80 mm to 1200 mm for accurate positioning and repeatable cuts.

|

V-roller conveyorThe BSM 450 V-roller conveyor in bolted design is a free-standing, non-driven roller conveyor with a length of 3000 mm, a width of 580 mm and a height of 870 mm. It serves as a supporting structure for the handling and precise positioning of work pieces during the sawing process on the BSM 450. This roller conveyor provides a stable and reliable basis for the safe processing of plastic pipes. |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Technical data |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Plastic pipes, composite pipes and plastic pipes made of solid and hollow sheets

are commonly used in manufacturing and construction for transportation purposes

of various media (e.g. water, sewage and rainwater transport) and as a part or

self-contained structural elements. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ROTHENBERGER ROWELD® BAND SAW MACHINES |

| ||

|

RIEXINGER BSM-450 BAND SAW MACHINE Ø 50mm - 450mm |

|

|

All content © Copyright 2025 CMS Industrial Equipment Corporation |